Page 1 of 1

Troubleshooting my V8 stirling

Posted: Thu Sep 23, 2010 11:01 pm

by bogan

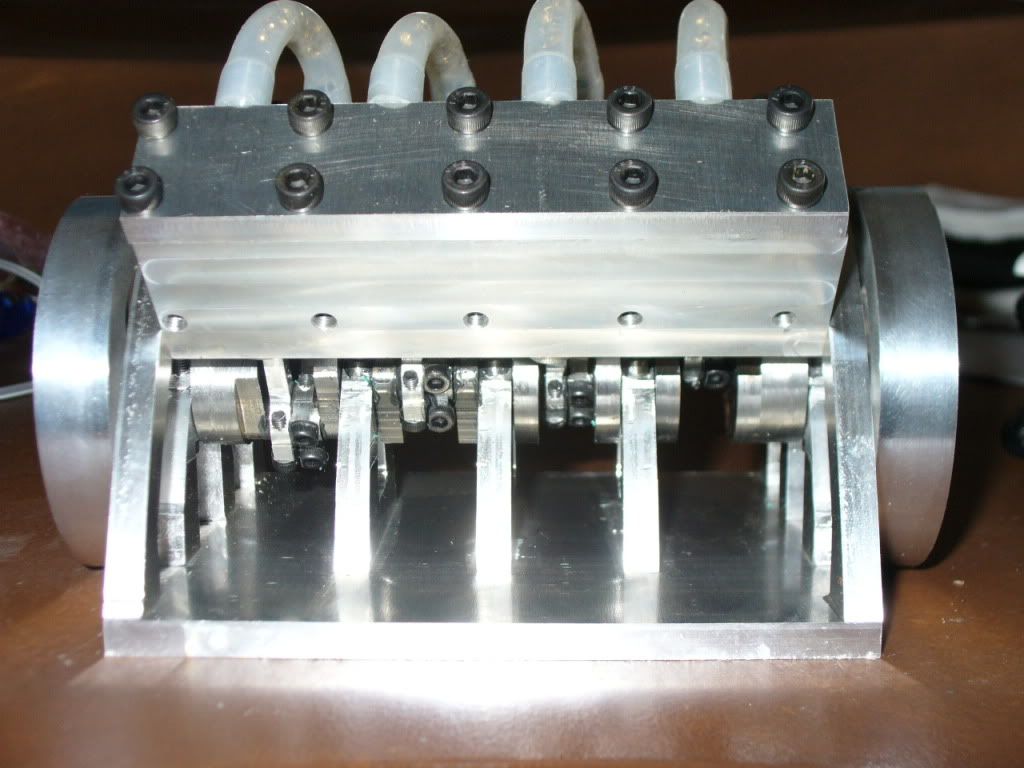

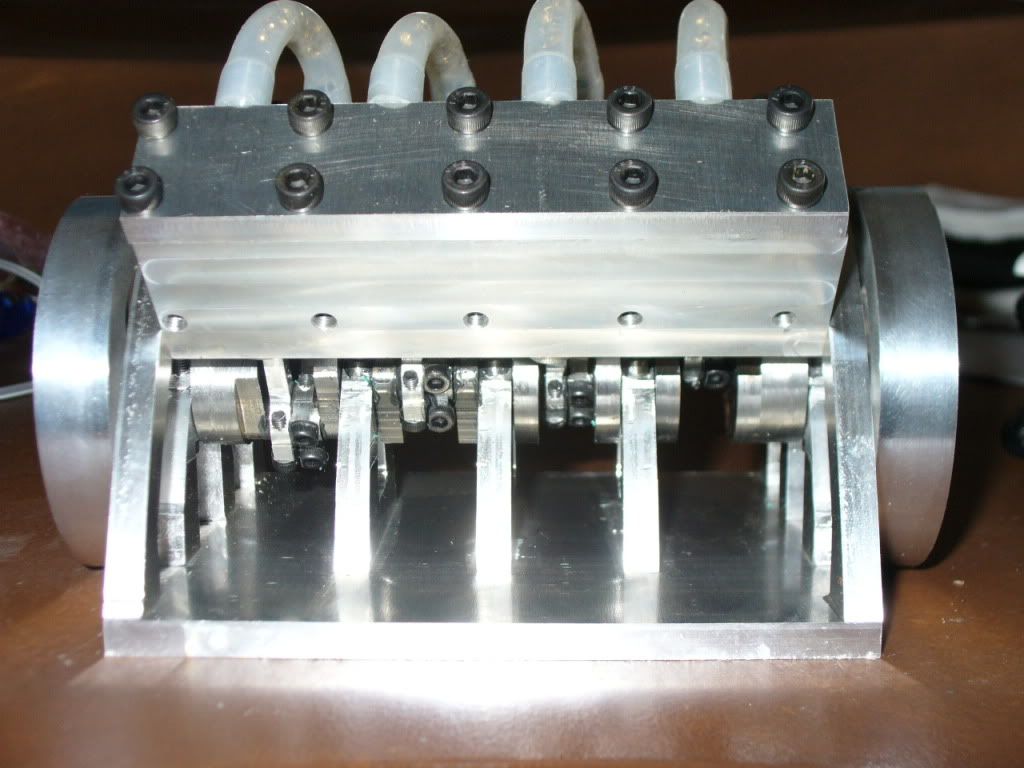

Machined up a v8 block and crank, decided to try and make it into a stirling engine. Alpha type with the pistons on each shared crankpin also sharing the working fluid. It's a standard crossplane 90degree V8 design, will heat one bank and cool the other. No rings on the piston or oiling, just a precision machined fit.

20mm diameter pistons with 15mm throw. Which gives a swept volume of 4.6cc per cylinder. Think I mucked up the head design a bit and currently have 1.7cc unswept volume in there for each cylinder, plus another 1.5cc in the regenrator/hose (jammed some copper/zinc wool int the hose to act as a regenerator).

Its fairly easy to turn over until i connect the cylinder together with the hose, then it gets a lot harder, which i assume is how it's sposed to be.

We tried it today, was definitely easy to turn over the correct way once there was heat in it, but just won't turn over by itself. Is it likely to be the unswept volume ratio? cos currently 50% of the volume in each pair is unswept, and the regenerator creates a flow restriction...

Re: Troubleshooting my V8 stirling

Posted: Fri Sep 24, 2010 12:52 am

by Junkie

Try disconnecting the hose/pipe between the cylinders, whilst the engine is heated, then reconnect it, it might run then.

Re: Troubleshooting my V8 stirling

Posted: Fri Sep 24, 2010 9:29 pm

by bogan

Tried that but no go. Did some checking of various things today, getting bout 15psi compression on each of the cylinders when spun up with a cordless drill, but also takes 3A @15.5V to spin it up to around 400rpm when the hoses are connected (and temperature differential applied), 2.6A when not, obviously a cordless dril isn't 100% effecient, but even if it take 15W to spin, that still sounds like a lot. So looks like there is too much friction in it to run, bugger. Perhaps a steam conversion is a better idea...

Re: Troubleshooting my V8 stirling

Posted: Sat Sep 25, 2010 4:12 pm

by bogan

will try giving it a good run soon and see what sort temperature differential it can generate, guess that'll let me know for certain whether its a friction issue or sealing issue.

Re: Troubleshooting my V8 stirling

Posted: Sat Sep 25, 2010 4:58 pm

by bogan

it does generate a bit of a temperature difference, bout 15-20deg after a few min at 1000rpm. Will try and find a little dc motor to belt drive to the flywheel then get some proper measurements, that way even if it doesn't work as a stirling it'll still spin (decided steam is way too difficult with all the valves etc, and would corrode my piston and crank well quick!).

Anyway, heres some pictures of it

Re: Troubleshooting my V8 stirling

Posted: Sun Sep 26, 2010 2:27 pm

by bogan

4040 steel pistons with aluminium bores, no crowns, heat/cool is applied to the side of the blocks, was gonna figure out what sorta temp it need to be to run then bolt on appropriate equipment, water baths, or heatsink and thermal mass etc... except I haven't been able to get it running yet!

Re: Troubleshooting my V8 stirling

Posted: Sun Sep 26, 2010 2:54 pm

by Junkie

What are those hoses made of ? Why haven't they melted when you heated it up?

Re: Troubleshooting my V8 stirling

Posted: Sun Sep 26, 2010 2:59 pm

by bogan

not sure what grade plastic they are, only heated it to about 150degrees centigrade so far, then the grease on all the bushings starts smoking.

Re: Troubleshooting my V8 stirling

Posted: Mon Sep 27, 2010 12:55 pm

by Longboy

......Ian is so right here. You will have to rework one cyl. head for heat caps. Lay aside the regenerator material for now and experiment with it after you have a running engine. Your crank and rod bearings have to be ball bearings with no or steel shielding. Minimum piston crowns, just enough to support them in the bore. This is just anti friction fighting but with plain bearings your engine is D.O.A. and you don't describe the bearings in your text. Muti cyl. engines should be trouble shooted by isolating its cylinders by pairs. In a V-8, start up as a twin (4 cylinders) front, middle and rear quad sets. A dead cylinder means a dead engine in Stirling. A pair of hot and cold cylinders should (may) be enough to overcome the friction of the inactive cylinders. You may have to go farther than just disconnecting the heat transfer tubes from the inactive cylinders and may have to remove those piston/rod assemblys from the crank so the "in testing" cylinders have a greater chance of rotating the flywheel under heat. Its a great looking engine and may be ready to run right after you engineer the heat caps!

Re: Troubleshooting my V8 stirling

Posted: Mon Sep 27, 2010 1:28 pm

by bogan

hmmm, looks like its only gonna be an awesome paperweight then, rather than an awesome stirling! The ally is only good for 600deg then it melts, anywhere close to that and I would be worried about leaving the torch flame on too long and melting little bits. And no to bearings, the crank is machined out as two halves so impossible to get bearings in there, so I also didn't bother with small end bearing either (was 4mmdia small too!).

From what you guys have said I think it'd be less work to start from scratch than re-engineer the V8, thanks for the advice!

Re: Troubleshooting my V8 stirling

Posted: Tue Sep 28, 2010 1:43 pm

by bogan

no room for any ball races on the crank, and not really up for all that other machining. The main goal was to make up a mini v8, and i figured it'd be cool to have it run in some configuration, went with stirling cos it sounded the easiest, now I'm thinking compressed air or steam is gonna be significantly easier.

Re: Troubleshooting my V8 stirling

Posted: Tue Sep 28, 2010 4:58 pm

by Longboy

bogan wrote:hmmm, looks like its only gonna be an awesome paperweight then, rather than an awesome stirling! The ally is only good for 600deg then it melts, anywhere close to that and I would be worried about leaving the torch flame on too long and melting little bits. And no to bearings, the crank is machined out as two halves so impossible to get bearings in there, so I also didn't bother with small end bearing either (was 4mmdia small too!).

From what you guys have said I think it'd be less work to start from scratch than re-engineer the V8, thanks for the advice!

............Ya the idea in Stirling is to heat up the air inside of the engine, not cook the engine. Thats what the hot caps are for. A place to dirrect the flame at. The body of the model along with a radiator disperses the waste heat. Applying the torch to the side of the cylinder block invites a meltdown. We await your more thought out approach in a successful Stirling build!

Re: Troubleshooting my V8 stirling

Posted: Tue Sep 28, 2010 5:05 pm

by bogan

haha, yes that sounds like a much more intelligent way of doing it, think I basically overestimated the power output, and underestimated the heat required. Will probably get onto it again at some point, however I have a few motorbike mods to attend to atm :D

Re: Troubleshooting my V8 stirling

Posted: Wed Sep 29, 2010 8:50 pm

by bogan

Ian S C wrote:Bogan, Maybe a bit of a rest, don't give up altogether. Yes 4mm is on the small side for bearings, for good wear think a little big rather than small. main bearings could be needle rollers direct on the shaft. Good bronze bearings of the Oillite type are good also. One thing with the stainless hot caps the heat won't get to the aluminium. One thing that makes this type simple,the bore and stroke of both (hot & cold) cylinders are the same. From what I see you have the basis of a workable engine. Go work on the bike, don't kill yourself. Ian S C

nah way less work to turn it into an air engine, then make a proper stirling later on with all the advice you've given (maybe even post the design before building it

). And don't worry bout me dying on the bike, it's not even that dangerous, the government just wants joe public to think it is so they get away with overtaxing us

(I'm in NZ too btw).

Re: Troubleshooting my V8 stirling

Posted: Fri Nov 30, 2012 2:19 pm

by Coogrrr

Bogan - I applaud that you can make such a nicely milled engine I only wish I had a mill to do the same. Still I believe there is hope for this little engine to be a stirling and as a proof of concept that a regular US V8 could be converted I would love to see you continue forward. Awesome engine and I am rooting for you all the way!

Coog