Power piston sideloading: possible solutions

Posted: Sat Mar 10, 2012 10:31 am

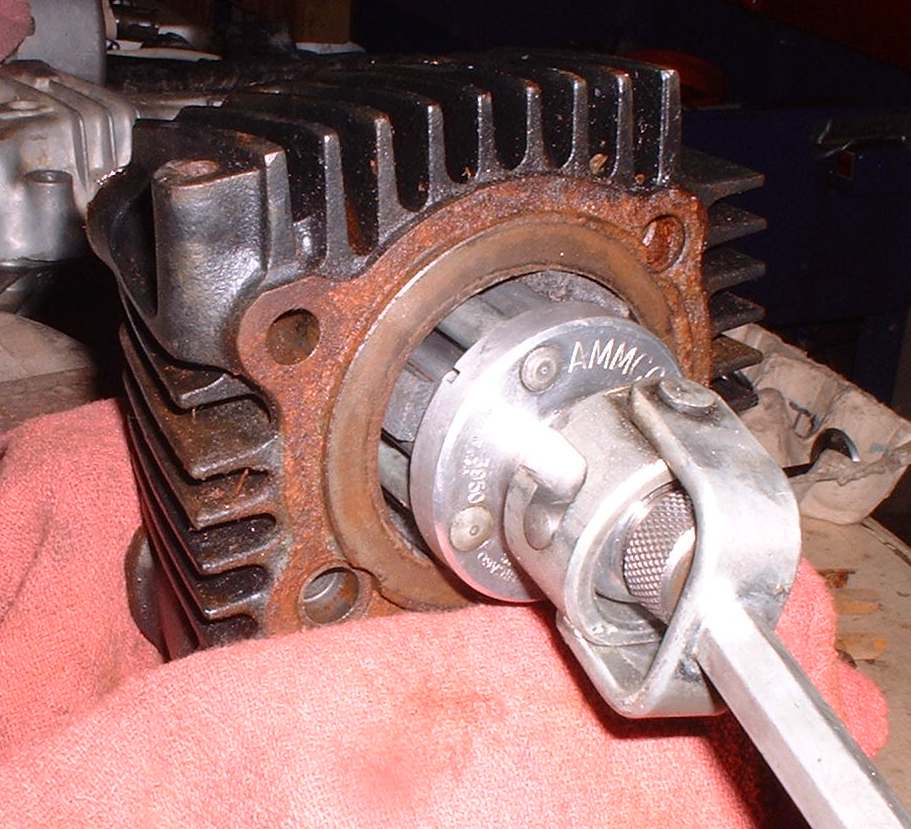

I was wondering if anyone had tried this on a large engine. Using a u-joint type coupling to the power piston. The picture is that of a cylinder hone, but you get the idea. It was meant to prevent sideloading and insure a smooth movement. This way, the power piston can stay concentric in the bore and reduce the friction as well as increase the speed due to the same fact. The downside is that it adds a little weight to the piston and rod. But if you don't feel like lapping another piston in the bore and like the part to live longer....this might be a solution. I won't be using it for my v-twin stirling, because everything is already laid out perfect for me. It would allow a quick and dirty build for prototypes, though.

A lighter weight solution could be a nylon ball and socket joint like those used in RC cars and planes. Should work for the smaller engines.

A lighter weight solution could be a nylon ball and socket joint like those used in RC cars and planes. Should work for the smaller engines.