For those who are joining in, I'll repeat my original question and add one more.

Q#1: Displacer volume versus Surface area what's important?

It looks to me as if the displacer should be given volume to offset the power piston but that surface area could be used to good effect as well. In considering the LTD Gamma Stirling a finned displacer would allow for quicker cooling of air in the upper half of the large displacer cylinder.

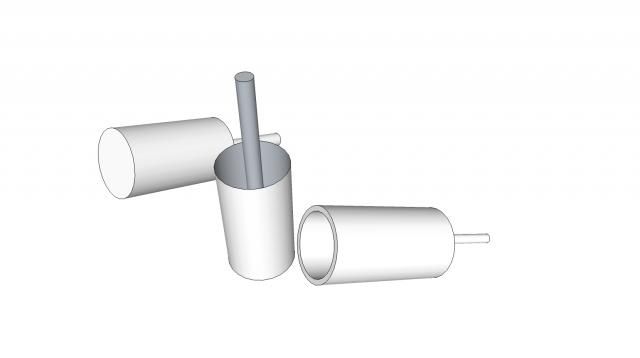

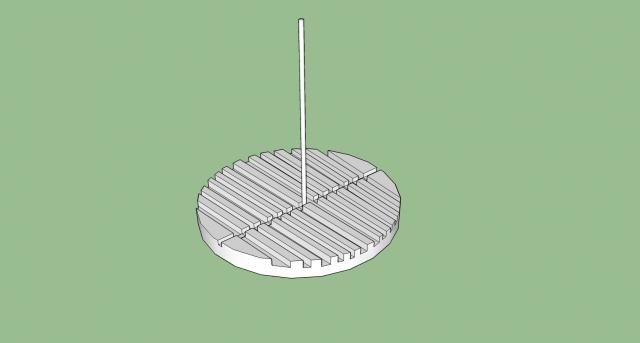

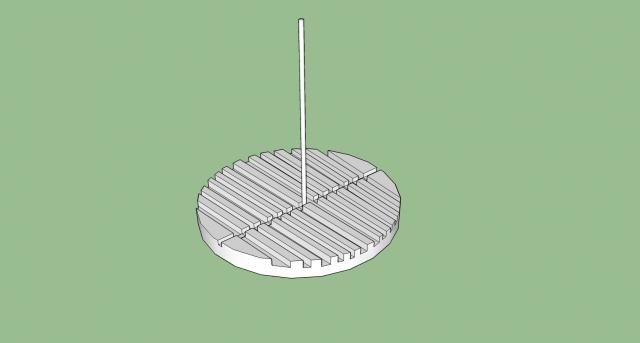

Another crude Sketchup representation:

Here I just started to show some of the fins and didn't draw all of then in both directions. Nor did I pay any real attention to spacing.

Q#2: is there a good way to calculate the needed ratios for displacers and is that

different for Gamma or Betas, or the same?

The LTD I have on my desk has roughly the following dimensions.

1. The length of the displacer chamber = 3 times is diameter.

2. The length of the heated chamber = 2/3 of the length of the displacer chamber (cylinder).

3. The length of the cooling chamber = 1/3 of the length of the displacer cylinder.

4. Swept volume of the displacer = 1 1/2 times the swept volume of the power piston.

5. Length of the displacer = 2/3 of the length of the displacer cylinder.

6. Stroke of the displacer = 1/3 of the length of the displacer cylinder.

Does anyone have any better suggestions or rules of thumb to work off of?