Anyone,animation of ericsson cycle engine.

-

fullofhotair

- Posts: 265

- Joined: Sun Aug 05, 2012 6:28 am

Anyone,animation of ericsson cycle engine.

I would like to see a good animation of an ericsson cycle engine. I need to see how the timing and off set was done mechanically.

Re: Anyone,animation of ericsson cycle engine.

Write in "Ericsson hot air engine animation" in google. there are a number of utube vidios, at least one has an animation .

At the moment Model Engineer magazine is running a build article on a Dean Myers Rider - Ericsson hot air engine kit, this one is quite large, with a 3" bore, and a 13" flywheel. Dean Myers also seem to make a kit for two smaller motors, 2" and 1", think it must be an American company.

The Model Engineer numbers are Vol 211, No. 4459, 4461, 4463, not sure how many more. Ian S C

At the moment Model Engineer magazine is running a build article on a Dean Myers Rider - Ericsson hot air engine kit, this one is quite large, with a 3" bore, and a 13" flywheel. Dean Myers also seem to make a kit for two smaller motors, 2" and 1", think it must be an American company.

The Model Engineer numbers are Vol 211, No. 4459, 4461, 4463, not sure how many more. Ian S C

-

fullofhotair

- Posts: 265

- Joined: Sun Aug 05, 2012 6:28 am

Re: Anyone,animation of ericsson cycle engine.

Ian SC

I got all excited using that google entry, then realized the animation was Ericssons stirling engine. I want to try and make a tin can ericsson cycle engine using 2 diaphrams for pistons. The cold and hot side piston seem to be attached to the same con rod. The hot cylinder is larger than the cold. The cold side has two one way valves. I want to use either steel or plastic leaf valves there. The pressure vessel will just be another enclosed can. Aquarium tubing will lead from pressure vessel to cylinders. A medium sized tube filled with steel wool will be the regenerator.??? My big question is how do I open and close the valves on the pressure vessel? Is this like the 90 degree off set on the stirling engine? The valve seems to just be open or closed. The only way I can think of to do this, is to have a small copper cylinder with holes along the side ,in the two capped ends ,as the little piston continually moves up and down, it aligns with different holes. If anybody has any suggestions I would really appreciate them. It seems like this engine has a lot of dead space compared to a stirling. Iam really interested in air output. A little bubbler in a water tank.

I got all excited using that google entry, then realized the animation was Ericssons stirling engine. I want to try and make a tin can ericsson cycle engine using 2 diaphrams for pistons. The cold and hot side piston seem to be attached to the same con rod. The hot cylinder is larger than the cold. The cold side has two one way valves. I want to use either steel or plastic leaf valves there. The pressure vessel will just be another enclosed can. Aquarium tubing will lead from pressure vessel to cylinders. A medium sized tube filled with steel wool will be the regenerator.??? My big question is how do I open and close the valves on the pressure vessel? Is this like the 90 degree off set on the stirling engine? The valve seems to just be open or closed. The only way I can think of to do this, is to have a small copper cylinder with holes along the side ,in the two capped ends ,as the little piston continually moves up and down, it aligns with different holes. If anybody has any suggestions I would really appreciate them. It seems like this engine has a lot of dead space compared to a stirling. Iam really interested in air output. A little bubbler in a water tank.

Re: Anyone,animation of ericsson cycle engine.

Here's some examples and websites that might be helpful:

http://en.wikipedia.org/wiki/Ericsson_cycle

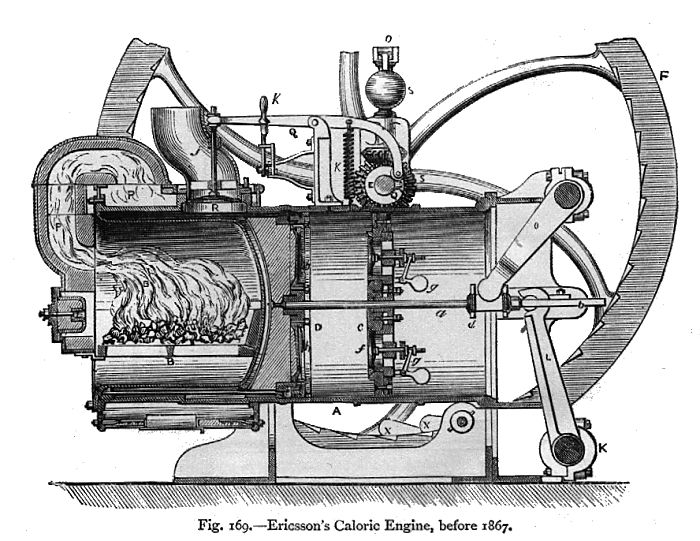

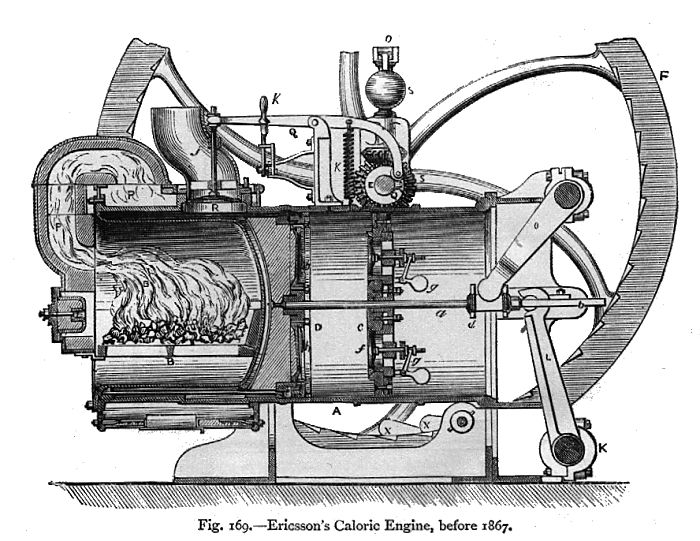

This example has a "two in one" moving piston and is a final evolution of his Ericsson cycle engine. (I think)..

http://manson-ericsson-hae.blogspot.com ... -that.html

The jpg below is the same design but is a better example of how it can be configured using one way valves

http://www.nmri.go.jp/eng/khirata/stirl ... ral_e.html

[hr]

This example has 2 pistons and more moving components etc, but less dead space, although no capacity for a regenerator, and is his original Caloric engine concept (i think)..

If you go to the webpage you are able to play with the gif

http://www.odts.de/hot_air/ericsson/strandh.htm

[hr]

Have you come across the Manson Hot Air Engine before?

http://manson-ericsson-hae.blogspot.com.au/p/ma.html

vamoose

http://en.wikipedia.org/wiki/Ericsson_cycle

This example has a "two in one" moving piston and is a final evolution of his Ericsson cycle engine. (I think)..

http://manson-ericsson-hae.blogspot.com ... -that.html

The jpg below is the same design but is a better example of how it can be configured using one way valves

http://www.nmri.go.jp/eng/khirata/stirl ... ral_e.html

[hr]

This example has 2 pistons and more moving components etc, but less dead space, although no capacity for a regenerator, and is his original Caloric engine concept (i think)..

If you go to the webpage you are able to play with the gif

http://www.odts.de/hot_air/ericsson/strandh.htm

[hr]

Have you come across the Manson Hot Air Engine before?

http://manson-ericsson-hae.blogspot.com.au/p/ma.html

vamoose

Last edited by vamoose on Sat Aug 03, 2013 11:29 pm, edited 1 time in total.

-

fullofhotair

- Posts: 265

- Joined: Sun Aug 05, 2012 6:28 am

Re: Anyone,animation of ericsson cycle engine.

Thanks Vamoose

Those were some good animations. Ericsson used those elbow con rods which makes figuring out the timing difficult. It looks like it could be a 90 degree off set? I think if I use a wire crankshaft I can connect the hot end valve to open and close. The valve seems to be on or off. By using a copper tube with long fat slits, and jb weld piston, I should be able to get the on off for the 2 one way valves.

Those were some good animations. Ericsson used those elbow con rods which makes figuring out the timing difficult. It looks like it could be a 90 degree off set? I think if I use a wire crankshaft I can connect the hot end valve to open and close. The valve seems to be on or off. By using a copper tube with long fat slits, and jb weld piston, I should be able to get the on off for the 2 one way valves.

-

bladeattila

- Posts: 44

- Joined: Wed Aug 21, 2013 10:31 pm

- Location: Budapest, Hungary

Re: Anyone,animation of ericsson cycle engine.

How did it work...with some comments: https://www.youtube.com/watch?v=0dqrRpV76sk

The flames of ignorance doesn't hurt when you burn.