varible phasing

Re: varible phasing

There is a video on U Tube of a bloke in USA who has a Stirling Engine tractor, think his name is Jim Tangman.

Ian S C

Ian S C

-

fullofhotair

- Posts: 265

- Joined: Sun Aug 05, 2012 6:28 am

Re: varible phasing

I don't think I explained my idea very well. You would have a gamma using two flywheels for timing. They are connected by a shaft .The power piston flywheel is round, only the displacer flywheel is odd shaped. By using a graph you decide the shape of the displacer flywheel. Flatter at the bottom to hold the displacer longer at the hot side ,etc.

Re: varible phasing

all valve gears on steam engines work on way that change phase angle and stroke of valve relative to piston.

maybe some of simple valve gears can be easy modified to change phase angle with small variation in stroke.

I was thinking about changing power and direction of gamma engine by changing stroke of power piston. idea was to use modified Klug valve gear

Here it is idea: https://www.dropbox.com/s/kid8dlhws6y45 ... irling.bmp

lots of valve gear simulators you have on this site: http://www.billp.org/Dockstader/ValveGear.html

Salute

maybe some of simple valve gears can be easy modified to change phase angle with small variation in stroke.

I was thinking about changing power and direction of gamma engine by changing stroke of power piston. idea was to use modified Klug valve gear

Here it is idea: https://www.dropbox.com/s/kid8dlhws6y45 ... irling.bmp

lots of valve gear simulators you have on this site: http://www.billp.org/Dockstader/ValveGear.html

Salute

Re: varible phasing

Fullofhotair, you need equal times at both ends of the stroke, it's just as important to lose heat, as it is to gain it. Slow at each end and fast in the middle.

My books on cycling do not have anything good to say about elliptical sprockets, other than to say that if they were that good every bike would have them, watch the professionals. Ian S C

My books on cycling do not have anything good to say about elliptical sprockets, other than to say that if they were that good every bike would have them, watch the professionals. Ian S C

-

fullofhotair

- Posts: 265

- Joined: Sun Aug 05, 2012 6:28 am

Re: varible phasing

Ian SC

I thought I remembered post on this forum talking about attempts at holding the displacer a little longer at the hot end ,as this would be an advantage. Obviously the elliptical gear is out, but is there an plus at all in doing this? I thought I also remember people talking about using reed valves to some advantage?

I thought I remembered post on this forum talking about attempts at holding the displacer a little longer at the hot end ,as this would be an advantage. Obviously the elliptical gear is out, but is there an plus at all in doing this? I thought I also remember people talking about using reed valves to some advantage?

Re: varible phasing

I wouldn't count out an elliptical gear to achieve what is being discussed.

If you look at the 'gif' below you can see the 'Right' gear is spinning at a constant rotational speed (this would have the flywheel attached and also be attached to the power piston),

Where as the 'Left' gear spin speed (slave gear), has precisely the right scenario for faster stroking between ends, and longer hang-time at both ends of the displacer stroke .. faster 90°- slower 90°- faster 90°- slower 90°

(as long as the displacer crank orientation is correctly located, of course)

vamoose

If you look at the 'gif' below you can see the 'Right' gear is spinning at a constant rotational speed (this would have the flywheel attached and also be attached to the power piston),

Where as the 'Left' gear spin speed (slave gear), has precisely the right scenario for faster stroking between ends, and longer hang-time at both ends of the displacer stroke .. faster 90°- slower 90°- faster 90°- slower 90°

(as long as the displacer crank orientation is correctly located, of course)

vamoose

Re: varible phasing

I was thinking about this solution

this is first two elements of Furirer row for "right angle" sine function on mechanical way.

in this solution displacer is in average 20% higher from center in first 180° and same thing but opposite direction in another 180°

seams to me like easy way to make, but my opinion is that all that systems make more friction compared with additional power.

Salute

this is first two elements of Furirer row for "right angle" sine function on mechanical way.

in this solution displacer is in average 20% higher from center in first 180° and same thing but opposite direction in another 180°

seams to me like easy way to make, but my opinion is that all that systems make more friction compared with additional power.

Salute

Re: varible phasing

Nice configuration Ante! I think many of us, have at some time, thought about the dynamics of timing and stroking variations. I've definitely scribbled down many different wacky approaches.

Although thinking about it and experimenting with it are 2 different things. Also, determining if there are any benefits to be gained over the added complication is another head scratcher.

Still I’ve been enjoying the discussion and everyone’s thoughts so far, and hopefully it might plant a seed or inspire a useful idea for other members or readers wishing to experiment with such things.

Thanks for the Topic post aero..

vamoose

Although thinking about it and experimenting with it are 2 different things. Also, determining if there are any benefits to be gained over the added complication is another head scratcher.

Still I’ve been enjoying the discussion and everyone’s thoughts so far, and hopefully it might plant a seed or inspire a useful idea for other members or readers wishing to experiment with such things.

Thanks for the Topic post aero..

vamoose

-

120ThingsIn20Years

- Posts: 7

- Joined: Fri May 03, 2013 8:55 pm

Re: varible phasing

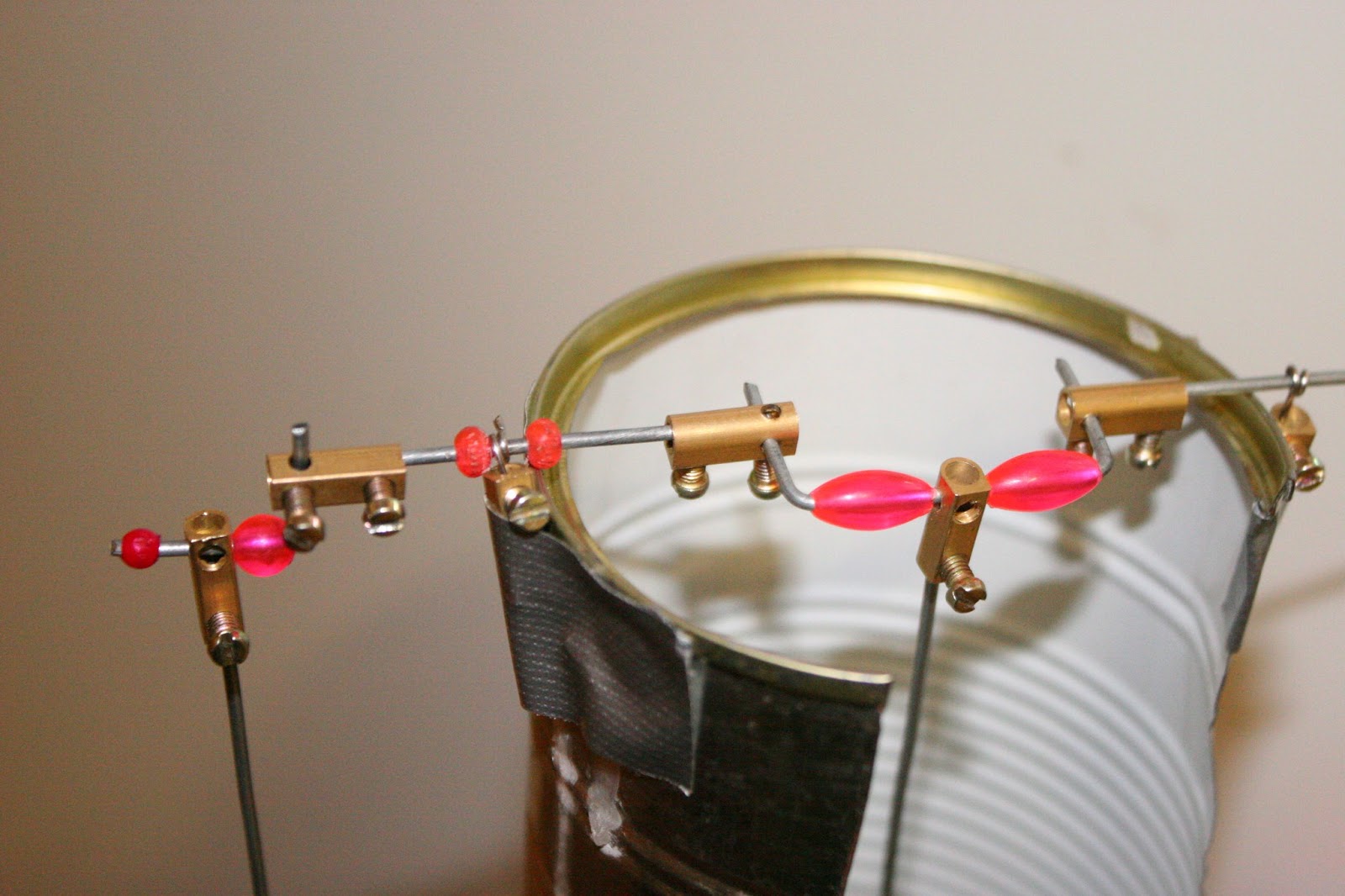

I made this as a way to explore the results of adjusting the crank shaft on my little tin can Stirling engine...

Perhaps the most useful bit is the fact that the mounting that holds the bearing surface is removable allowing the entire thing to be replaced. This fact allowed me to add real bearings to essentially the same shaft to see how much drag it added...

I'm in the process of formalizing a problem solving technique, so creating an outline for a dynamically adjustable phase crank shaft thing might be a really good test for it.

Wish me a stack of luck :)

And just in case anyone cares, it turns out to be around 1/4 of a tea-light flame extra is required to get the same speed. ie where it ran on a single tea-light at 100rpm with wire bearings, with 2 ball bearing races instead, it now requires an extra flame. I trimmed the second tea-light so it's flame was around 1/4 of a normal tea-light (flame size just judged by eye)

The two bearings were lifted out of a 5cm chip cooling fan (harder to do than you might think)

Perhaps the most useful bit is the fact that the mounting that holds the bearing surface is removable allowing the entire thing to be replaced. This fact allowed me to add real bearings to essentially the same shaft to see how much drag it added...

I'm in the process of formalizing a problem solving technique, so creating an outline for a dynamically adjustable phase crank shaft thing might be a really good test for it.

Wish me a stack of luck :)

And just in case anyone cares, it turns out to be around 1/4 of a tea-light flame extra is required to get the same speed. ie where it ran on a single tea-light at 100rpm with wire bearings, with 2 ball bearing races instead, it now requires an extra flame. I trimmed the second tea-light so it's flame was around 1/4 of a normal tea-light (flame size just judged by eye)

The two bearings were lifted out of a 5cm chip cooling fan (harder to do than you might think)

My skills include being able to move slowly forward in time, and if I really concentrate, I can sometimes tell what I'm thinking.

Re: varible phasing

For the record, you can also get small ball bearings out of certain types of computer back-up tapes - I've grabbed a few from DLT tapes.

But am I reading you correctly - the 'proper' ball bearings have _more_ friction than your 'hand made' bearings?

But am I reading you correctly - the 'proper' ball bearings have _more_ friction than your 'hand made' bearings?

Re: varible phasing

To reduce the friction of ball bearing races, remove the shields on the side of the bearing, and flush out the grease, oil with very light grade oil (sewing machine).

Ian S C

Ian S C

-

cbstirling2

- Posts: 156

- Joined: Sat Dec 17, 2016 9:35 pm

Re: varible phasing

Rereading the book today. Had similar thoughts. Neat to read other people's ideas.aero wrote:In Andy Ross's book he mentions that he tested phasing from 60 degrees to 180 degrees with interesting results at narrower angles the compression became higher and more difficult to start and required higher temperatures even to run. But when it did run "it did so with great power and speed". As the angle increased the engine was easier to start and had less power and speed but would run at lower temperatures. Now is anyone using variable timing?

I see the variable timing as a why to optimize the engine power output for the conditions and for quicker starts.

Basically on startup the engine should have large phase and later after warming up or depending on load, a narrow angle.

I think Ian's suggested of a variable gamma seems most simple but Andy basically trashed the gamma design in his book...

CBStirling2

-

Aviator168

- Posts: 308

- Joined: Tue Feb 08, 2011 2:29 pm

- Location: Brokeville, NY. USA

Re: varible phasing

Yes. If you increase the temperature and change the phasing to close 0, it looks like an IC. Oh, you can get rid of the cold cylinder too. The point of a stirling engine is common material can be used and some how produce the comparable amount of power. In order to do that, the power from suction needs to be utilized.