Hi everybody

I'm developing a stirling engine that is going to the back of the wood burning stove and the main purpose is to generate some electricity. Also the engine will be pressurised to gain more energy out of it.

I have been looking through the forum to find the best solution for displacer piston rod seal. I have found some solutions on this link - http://stirlingengineforum.com/viewtopic.php?f=1&t=1003 The solution I know is to make the rod perfectly fit to the hole. Could anybody give any other elegant solution for this problem?

Thanks in advance

Alex

Elegant solution for the rod seal

Re: Elegant solution for the rod seal

For a pressurised engine there is no more need for sealing the displacer than in any other motor as both sides of the seal are pressurised, the place that requires careful sealing is the crankshaft where it exits the crankcase, ideally the crank would not come through the case, but if it must (usually does), have only one end that comes out and needs a seal, the important thing is to have the minimum of friction. It does not matter how powerful your motor, mili watts, or Kilo watts friction is proberbly the biggest robber of power. Ian S C

Re: Elegant solution for the rod seal

Ian Thank you very much for your reply.

It just can't stuck in my head that no seal is required. I have found a picture in your gallery and would like to ask, did you make a perfect fit on that place I have marked in the attachment??

For me it looks that there is something inside.

Alex

It just can't stuck in my head that no seal is required. I have found a picture in your gallery and would like to ask, did you make a perfect fit on that place I have marked in the attachment??

For me it looks that there is something inside.

Alex

Re: Elegant solution for the rod seal

Alex, that motor has got a carbon impregnated teflon bush in the gland, I'v used that on a number of engines, I'v also used plain brass, and cast iron, all with success. The teflon does give a low friction sliding bush, it won't be a perfect seal, but about as good as you get, low friction is the important one, the leak comes next. Ian S C

Re: Elegant solution for the rod seal

Hi Alex. I'm working on electricity from a woodstove too. My seal is sort of "elegant," but I've no idea yet if it will work. My displacer design uses a short stroke so the rod can move with a diaphragm, which also allows it to rock a little bit so there are no extra joints needed in the rod to the crank. The diaphragm is an isolated central portion of a much larger power diaphragm in a Beta design, and hopefully its movement won't upset the overall dynamics too much. It's meant to handle pressure, but probably less than two bar. Bumpkin

Re: Elegant solution for the rod seal

There was this thread:

http://stirlingengineforum.com/viewtopic.php?f=1&t=487

Haven't actually tried it though. Magnetic attraction and repulsion or levitation.

http://stirlingengineforum.com/viewtopic.php?f=1&t=487

Haven't actually tried it though. Magnetic attraction and repulsion or levitation.

Re: Elegant solution for the rod seal

Bumkin, your displacer may 'rock' a bit, but it must not touch the sides of the cylinder. Until someone proves different, I'll remain skeptical over the use of magnets to operate the displacer. Ian S C

Re: Elegant solution for the rod seal

Ian, the displacer won't hit the sides. The limited amount of rocking is a factor of how long the rod vs. how short the displacer, relative to the effective pivot point. I do admit though, to having difficulties getting enough diaphragm flexibility while maintaining enough lateral strength. I could always add a swing-arm right above the diaphragm if I have to. I'm not doing anything with magnets. Bumpkin

Re: Elegant solution for the rod seal

Sorry, it was Tom with the magnets, a few people have floated that idea. The place where magnets have worked are in one of Andy Ross's motors, a sealed yoke type ALPHA motor with the magnets driving the external flywheel, making it so that the crankshaft stayed internal, not needing seals. Ian S C

Re: Elegant solution for the rod seal

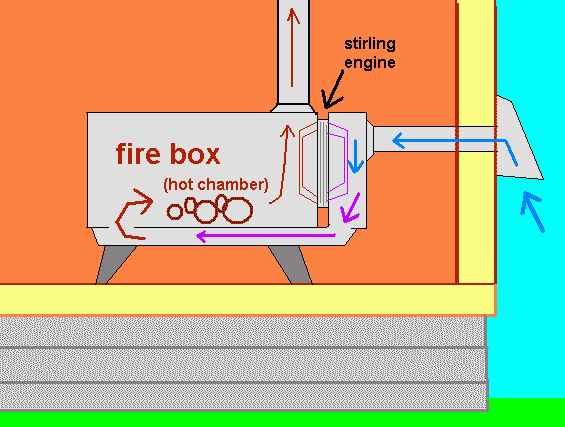

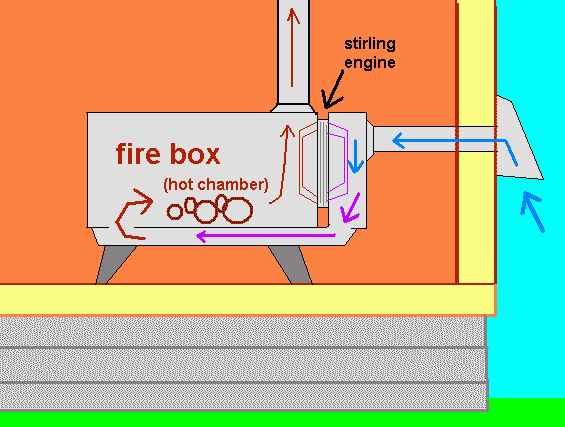

I had this design for a Stirling wood stove back in 2008:

This doesn't show any detail of the engine itself, but I imagined the displacer on a pivot at the bottom of the displacer so that it would rock back and forth. I thought this would be more energy efficient as the displacer would probably need to be of some heat resistant material. I was thinking along the lines of firebrick for the displacer (rather heavy material for a displacer). I figured having it "hinged" at the bottom would take the weight off.

Presumably, with such a displacer, it could be moved back and forth via a magnet at the top eliminating the need for any kind of seal. Since the displacer is rocking on end I don't think there would really be any danger of it going out of line and rubbing on the sides of the chamber or anything.

I got that idea from an engine design someone posted in here a long time ago that had a displacer that stood on end and rocked on a pivot. Kind of like a large LTD engine turned on its side. The displacer and the displacer chamber itself were both kind of V shaped.

From what I remember it worked quite well, running on solar energy with one side of the engine facing the sun. The pivot at the bottom took the weight of the displacer so it rocked back and forth rather easily. It also used a diaphragm instead of a piston.

Anyway, that was more or less what I in-visioned sandwiched between the cold air intake and the firebox.

This doesn't show any detail of the engine itself, but I imagined the displacer on a pivot at the bottom of the displacer so that it would rock back and forth. I thought this would be more energy efficient as the displacer would probably need to be of some heat resistant material. I was thinking along the lines of firebrick for the displacer (rather heavy material for a displacer). I figured having it "hinged" at the bottom would take the weight off.

Presumably, with such a displacer, it could be moved back and forth via a magnet at the top eliminating the need for any kind of seal. Since the displacer is rocking on end I don't think there would really be any danger of it going out of line and rubbing on the sides of the chamber or anything.

I got that idea from an engine design someone posted in here a long time ago that had a displacer that stood on end and rocked on a pivot. Kind of like a large LTD engine turned on its side. The displacer and the displacer chamber itself were both kind of V shaped.

From what I remember it worked quite well, running on solar energy with one side of the engine facing the sun. The pivot at the bottom took the weight of the displacer so it rocked back and forth rather easily. It also used a diaphragm instead of a piston.

Anyway, that was more or less what I in-visioned sandwiched between the cold air intake and the firebox.