In this abstract we can read:

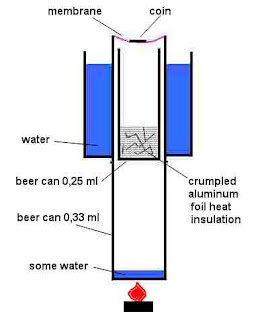

We present the thermodynamic cycle of the conversion in a wet, standing wave, thermoacoustic engine

Step(1) The mixture parcel moves towards the low pressure (also low temperature) region while being expanded adiabatically.

https://www.sciencedirect.com/science/a ... 4222015687

I see a few problems with this, first of all, the pressure in an enclosed volume of gas is pretty much always uniform I believe, or so I've frequently read in the literature on the behavior of gasses.

Think maybe, blowing up a car tire with a bicycle pump. The pressure, as the air is introduced, does not increase just around the valve or on one side of a tire, the pressure increases (or decreases if the air is let out) all through the entire volume of air inside the tire simultaneously. Same thing when inflating a balloon, etc. etc.

I mostly became aware of this while studying about the Vuilleumier heat pump, which takes advantage of this property.

https://en.m.wikipedia.org/wiki/Vuilleumier_cycle

When a chamber of gas is heated, the temperature and pressure of an adjoining chamber increases simultaneously.

Does something like a bunch of glass beads create enough of a restriction to maintain separate regions of high and low pressure? I very much doubt it.

Maybe some slight delay in pressure changes between the gas on the hot side and the gas on the cold side of the beads (or whatever medium) can be assumed, but personally I would not count on it or consider it significant when factoring together all the elements that comprise a running engine.

Be that as it may, the other issue I have with this description is the use of the term "adiabatic".

The gas moves to the cold region "while being expanded adiabatically".

I agree with the statement itself. What I have a problem with is the next step.

Next, in step (2) The compression makes the vapor pressure higher than the local equilibrium, resulting in condensation, which is accompanied by the heat rejection to the wall.

Were we not just told that the expansion takes place adiabatically?

Also, this is described as being "expanded adiabatically" but also as "the compression makes the vapor pressure higher".

I had to just double check and make sure that was not describing compression (or contraction) where the gas moves back down through the beads or mesh or whatever. No, we haven't gotten that far. That is described later in steps 3 and 4.

So the "adiabatic expansion" is the equivalent of "the compression".

Do the authors of this paper have any clear idea what they are talking about or what is actually going on? I don't really think so. $40 to read more? I don't think so.

Adiabatic expansion results in cooling and condensation all by itself. "accompanied by the heat rejection to the wall" - that I think is a contradiction, considering the definition of adiabatic.

Anyway, I think a more consistent and not self contradictory explanation would be that as a result of adiabatic expansion (along with cooling due to any work output, like lifting a big block of concrete) the gas cools and condenses on any available surface.

Generally under most ordinary circumstances condensation takes place due to hot humid air or water vapor giving up heat to something like a cold glass of lemonade on a hot summer day.

The dynamics inside a running engine, however are not such an ordinary circumstance. More like the expansion and cooling of rising hot humid air with cloud formation. In that case the air is not giving up heat to any surfaces. Well, dust particles ? I suspect dust particles in the air don't have much if any capacity to absorb heat.

I don't think that there is any necessity to postulate any "heat rejection to the wall" other than a perceived need to conform with the Carnot hypothesis.

,

,