Large LTD Diaphragm Gamma Stirling Questions

-

playludesc

- Posts: 9

- Joined: Sun Mar 04, 2018 10:16 am

Large LTD Diaphragm Gamma Stirling Questions

So I have an idea to eventually make a large, LTD Gamma type and bury it in my front yard. My hope is to use a design similar to the commonly homemade LTD toys. The general idea is that in the summer, the sun will heat the hot cap and the cold cap will be cooled by the soil. In the winter, the former hot cap will become the cold cap and the "hot cap" will be buried deep enough in the ground that it will be below the frost line and maintain the temperature differential via geothermal energy.

My questions are these:

Does the power of LTD gamma designs like these scale with size?

Is the pancake type design of all the LTD designs I see online necessary? My guess is this has something to do with minimizing the mass of the displacer while maximizing its ability to move air. Unfortunately, with as deep as I would need my bottom heat exchanger to be, this design might not be practical.

I've watched the Cody's Lab episode on pressurizing stirling engines, but I'm unclear as to whether it's necessary to pressurize not only the working gas but also the gas around the engine. If the issue of sealing the working gas is solved, it seems you could just pressurize the working gas... right? How does pressurizing the working gas affect diaphragm-type pistons?

I guess that's all of my questions, thanks in advance!

My questions are these:

Does the power of LTD gamma designs like these scale with size?

Is the pancake type design of all the LTD designs I see online necessary? My guess is this has something to do with minimizing the mass of the displacer while maximizing its ability to move air. Unfortunately, with as deep as I would need my bottom heat exchanger to be, this design might not be practical.

I've watched the Cody's Lab episode on pressurizing stirling engines, but I'm unclear as to whether it's necessary to pressurize not only the working gas but also the gas around the engine. If the issue of sealing the working gas is solved, it seems you could just pressurize the working gas... right? How does pressurizing the working gas affect diaphragm-type pistons?

I guess that's all of my questions, thanks in advance!

Re: Large LTD Diaphragm Gamma Stirling Questions

Large "pan cake" motors do work, there was a video on line of one in USA, it might have been ove 3ft in diameter. To get the right volume for the power cylinder, it actually used 3 cylinders working together.

In a pressurized engine, both sides of the motor is pressurized.

Ian S C

In a pressurized engine, both sides of the motor is pressurized.

Ian S C

Re: Large LTD Diaphragm Gamma Stirling Questions

playludesc,

I too am fascinated at the prospect of building a large LTD engine and so far have written many pages in planning such a project. I am in the process of scaling up an engine in four stages. Currently, I am on the second of four. If after building three successful models of increasing size then I may tackle a fourth one in a rather large size.

The displacer chamber can be square and can move on a vertical axis but there are other possibilites, the original Kolin engine had a square displacer which moved horizontally.

I have only a few books that are very helpful on this topic but I would like to mention them in case they may be helpful to others. First and foremost, the Senft book as it is both affordable and available, two wonderful qualities in a book ! It is "An introduction to Low Temperature Differential Stirling Engines".

"Stirling-Maschinen : Grundlagen, Technik, Anwendungen" by Werdich and Kübler; this book has quite a bit of information on large LTD engines in both theory and practice. It is extremely useful in developing both an understanding of the technical challenges of building a larger engine as well as a good overview of some of the larger engines built, including some technical data. It has an excellent section on understanding the physics involved in such engines.

One of my favorite books on this topic is "10 Moteur Stirling de Type Gamma" by Hubert Roussel. He gives such great suggestions in the details of building while meticulously exploring the power output of such engines in a way that can be understood with only a very rudimentary understanding of the math involved. (He has done all of the work for us :-) And although this book is confined to smaller models, he gives us some excellent examples of the development of an engine by trying different sized displacers, different strokes, timing, regenerators, ideas on capturing the energy, etc.

I hope that you will build your way up to this ! Do you plan to produce power with this or is it yard art ? Of course it can be both but I'm just wondering.

Good luck to you !

Alfista

-

playludesc

- Posts: 9

- Joined: Sun Mar 04, 2018 10:16 am

Re: Large LTD Diaphragm Gamma Stirling Questions

Do you mean that the space the power piston moves into on it's power stroke must be pressurized if the working gas is pressurized?Ian S C wrote:In a pressurized engine, both sides of the motor is pressurized.

-

playludesc

- Posts: 9

- Joined: Sun Mar 04, 2018 10:16 am

Re: Large LTD Diaphragm Gamma Stirling Questions

Thank you for the reading list Alfista! My original thought was for it to be a kinetic sculpture of sorts, but if I can get any appreciable power out of it, I'd love to put it to use. In the summer I'm thinking I could get as good as a 30-40°F temperature differential and maybe more in the winter if I can design something with a "deep" enough displacer chamber.

Large LTD engines as art

playludesc,

the Werdich and Kübler book covers some large LTD engines used as public art. They are interesting.

Yours sounds like a formidable project. Good luck to you ! If you build something, please post information about it, whether "successful" or "unsuccessful". We will learn something either way !

Thank you !

Alfista

-

playludesc

- Posts: 9

- Joined: Sun Mar 04, 2018 10:16 am

Re: Large LTD Diaphragm Gamma Stirling Questions

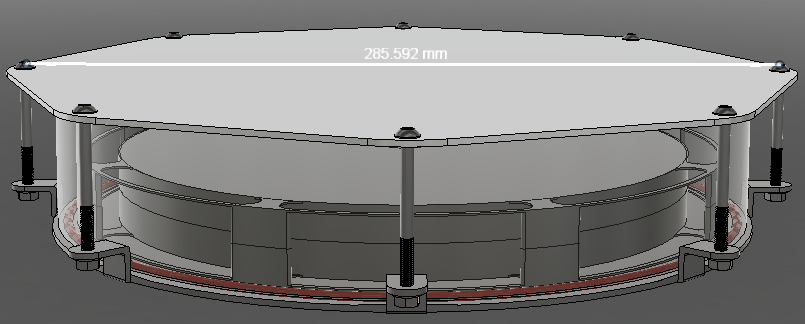

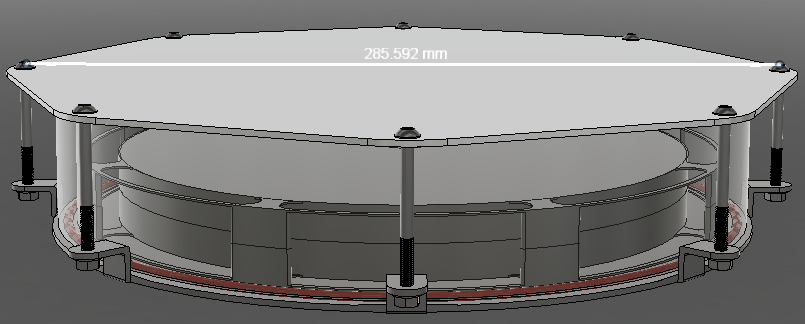

I've spent some of my free time the past couple weeks modelling the first prototype. I finished the displacer and it's cylinder and went to calculate how large I'll need to make the power piston and it's cylinder. Therein lies my newest problem: the swept volume of the displacer is almost two liters!

So far I've designed this to be as big as my 3D printer would accommodate, which is about 290mm x 290mm. The total volume of the displacer cylinder is about 2.34 liters. The displacer itself takes up about 1 liter after a rough guesstimate of how much dead space is left in the regenerator. I assume to maximize efficiency I'll want the displacer to move as much as possible, or in other words, I want it to shuttle virtually all of the air from the hot cap to the cold cap every stroke. That leaves me with a swept volume of pretty much 2 liters. Now if the bore x stroke of the power piston needs to be 66% of that... well, let's just say I'm at a loss.

My plan was to use condoms to create a diaphragm or free-piston system for the power piston(s), but 1.3 liters is a lot of condoms! Not to mention the pistons would have a much, much longer stroke than I was planning on accommodating.

So here are my questions this time:

Does the rule of swept volume of the displacer = 1.5 times the bore and stroke of the power piston apply to LTD engines?

Am I calculating the swept volume correctly? Does swept volume mean the volume of the displacer *and* the air it displaces? Or just the air it displaces?

Here's a screenshot of the model so far with a dimension to help give some perspective:

So far I've designed this to be as big as my 3D printer would accommodate, which is about 290mm x 290mm. The total volume of the displacer cylinder is about 2.34 liters. The displacer itself takes up about 1 liter after a rough guesstimate of how much dead space is left in the regenerator. I assume to maximize efficiency I'll want the displacer to move as much as possible, or in other words, I want it to shuttle virtually all of the air from the hot cap to the cold cap every stroke. That leaves me with a swept volume of pretty much 2 liters. Now if the bore x stroke of the power piston needs to be 66% of that... well, let's just say I'm at a loss.

My plan was to use condoms to create a diaphragm or free-piston system for the power piston(s), but 1.3 liters is a lot of condoms! Not to mention the pistons would have a much, much longer stroke than I was planning on accommodating.

So here are my questions this time:

Does the rule of swept volume of the displacer = 1.5 times the bore and stroke of the power piston apply to LTD engines?

Am I calculating the swept volume correctly? Does swept volume mean the volume of the displacer *and* the air it displaces? Or just the air it displaces?

Here's a screenshot of the model so far with a dimension to help give some perspective:

Re: Large LTD Diaphragm Gamma Stirling Questions

For a LTD motor the ratio is nearer 20:1. I think condoms for a diaphragm will have a similar life as they do in normal use, one shot then get another one, my experience with balloons is similar, and the motor didn't work any way.

Ian S C

Ian S C

LTD displacer to power piston ratios

There is a wide range of ratios that will work. Ususally, an LTD engine is in the range of 50:1 to 100:1.

You are trying to build an ultra low temperature differential engine. I would suggest a ratio of 60:1 to 61:1. If you do not read the Senft book on this topic before trying to design your own engine, then you are either a genius or a fool. He gives a full set of plans for the N-92.

There are some things that mostly work in your favor as you build larger: You can use relatively thinner rods and issues with bearings also work in your favor. Counterbalance the piston and counterbalance the displacer ! In this size, the regenerator is remarkably effective and therefore important.

As far as the displacer chamber goes. It is easier to build square than round and you can use wood to good effect ! It much easier ! You can put in a couple of viewing windows, if you want. I just finished a square engine, about 11" x 11". Having a somewhat thicker wall for the displacer chamber also makes it easier to seal but on a larger engine it will add more cost for gasket material but in such a low temperture range as the one you propose, neoprene should work fine and it is very inexpensive.

Alfista

Re: Large LTD Diaphragm Gamma Stirling Questions

My LTD motor has a power cylinder 15/16" bore x 1/2" stroke, the displacer is 6 1/2" x 1/2" stroke. The power piston is cast iron in a cast iron cylinder.

Ian S C

[img][/img]

Ian S C

[img][/img]

Re: Large LTD Diaphragm Gamma Stirling Questions

Beautiful engine Ian !! By my calculation, your engine has a 96.17:1 ratio. Does that sound right to you ? I also chose a cast iron piston in a cast iron cylinder for my lastest engine after first trying a bellows. The piston / cylinder arrangement was quite an improvement. After making such an engine, my hat is off to any machinist who can build such a piston and cylinder, given the care and precision required.

Wayne

-

playludesc

- Posts: 9

- Joined: Sun Mar 04, 2018 10:16 am

Re: Large LTD Diaphragm Gamma Stirling Questions

Ah, here is the image again. I forgot how much I hate photobucket.

Not shown: the ring around the outside of the displacer will be filled with aluminum wool.

Not shown: the ring around the outside of the displacer will be filled with aluminum wool.

Last edited by playludesc on Tue Mar 20, 2018 10:25 am, edited 1 time in total.

-

playludesc

- Posts: 9

- Joined: Sun Mar 04, 2018 10:16 am

Re: LTD displacer to power piston ratios

Thanks for those numbers! I wanted to get the Senft book, but the budget wasn't there to spend $45 on it. Can you help me clarify what is meant by "swept volume"? Does it mean the total volume of air displaced by the displacer? Or does it mean all the volume occupied by the displacer throughout a full cycle?Alfista wrote:

I would suggest a ratio of 60:1 to 61:1. If you do not read the Senft book on this topic before trying to design your own engine, then you are either a genius or a fool.

Thanks so much for the help!

-

playludesc

- Posts: 9

- Joined: Sun Mar 04, 2018 10:16 am

Re: Large LTD Diaphragm Gamma Stirling Questions

I spent some time thinking about it last night, and I'm pretty sure that a flatter design would be better than the one shown above. The reason being that in my current design, with such a large displacer stroke, the volume of air compared to the area of contact it has with the hot and cold caps is much too large--most of the air won't have a chance to change temperature before the next stroke. This will also let me have a somewhat lighter displacer, which should help with efficiency.

Re: Large LTD Diaphragm Gamma Stirling Questions

As far as cylinders go you just need to be able to bore it parallel, round, Then lap the bore to a high finish. You then make the piston, bringing it down in size until it just about fits in the bore, its then a case of polishing it down until it will just slide through the cylinder under its own weight, but when you block the end it stops, or just barely moves. The job takes time, quite a bit of it, but worth taking the trouble.

Ian S C

Ian S C