I thought I might mention something I've been working on recently and am also curious to know if anyone else here has ever heard of it or done anything with it.

https://en.m.wikipedia.org/wiki/Vuilleumier_cycle

This "heat pump" is quite interesting. I think the patent is quite facinating and informative.

Apparently the concept works and is quite efficient from what little I've been able to find out about it.

Anyway I THINK I've worked out a way of combining an ordinary small LTD type Stirling engine with a Vuilleumier heat pump so as to create a very simple and relatively easy to build realization of Tesla's Ambient heat engine that could "run on ice" that never melts.

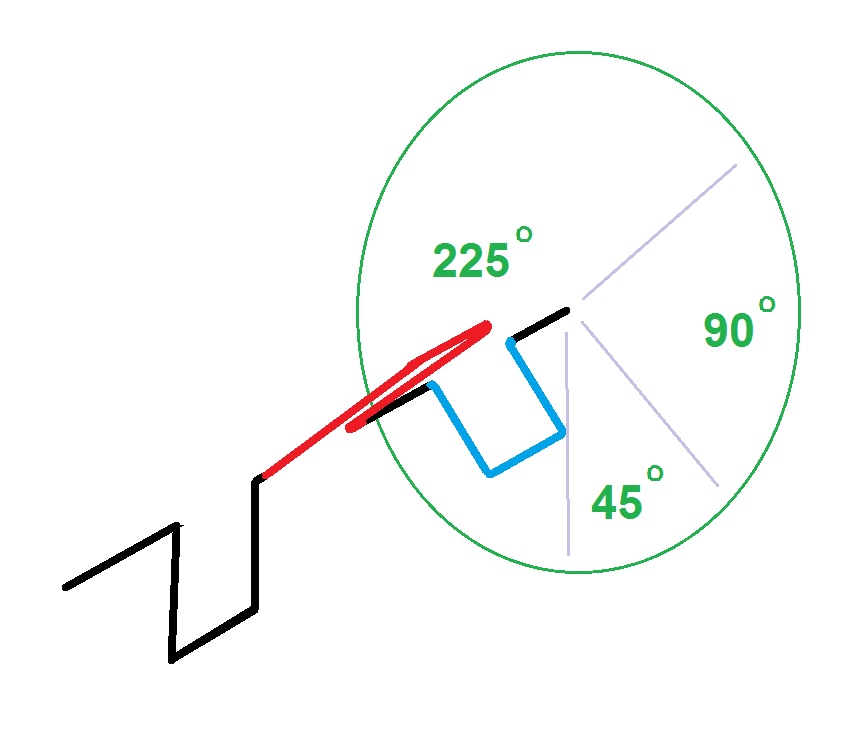

The basic concept is to add a second regenerative displacer to the bottom half of an ordinary LTD Stirling and have the movement of this displacer timed in such a way that it should absorb some heat from the ice that the stirling is running on.

In otherwords the Stirling running on ambient heat comming in from above will simultaneouly use some very little of its energy gained from the ambient heat to move a second displacer/regenerator that acts as a Vuilleumier type heat pump.

Put another way the engine will have two regenerators. One drawing heat from the warm ambient air above and the other drawing heat from the colder ice below. (Ice itself still contains a great deal of heat in actuality)

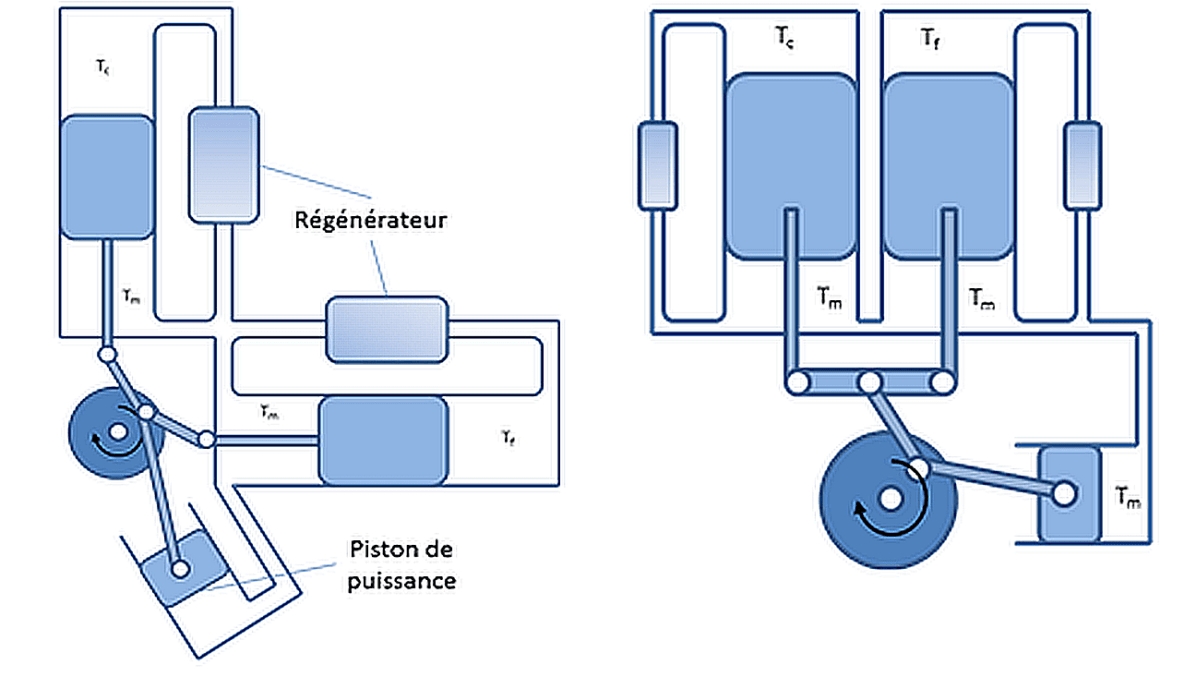

A. Vuilleumier heat pump itself functions in much the same way. Using two seperate regenerators to draw heat in from both ends.

The major difference is that a Vuilleumier heat pump outputs only heat and cooling but has no power output. So the idea in some respect is to take a Vuilleumier heat pump with two regenerators and incorporate a piston so that the heat is converted and output as "work" instead of heat.

I'm quite enthusiastic about this Vuilleumier heat pump.

I've designed some engines on the principle Tesla described before. Basically on the order of a Stirling engine being used to run a vapor-compression type heat pump using air as a "working fluid". That is, a Stirling engine running an air-cycle refrigerator to keep itself cool.

The main problem I've run into with that is, building such a thing, a combined Stirling engine and what amounts to a refrigerator combined required quite a bit of precission engineering and macine shop work for things like compressor piston & cylinder and an expansion turbine.. So I've been spending a lot of time and money trying to set up a machine shop. Which in itself has cost me thousands of dollars. Not only for the equipment but also for some space to set it all up.

Using a Vuilleumier heat pump for cooling as an alternative to an air-cycle system is, I think, much more straightforward, as well as much simpler and a whole lot easier to construct. All that is needed that would not be needed to build a little model LTD Stirling is a little extra steel wool for the additional regenerator.

That is, it can be constructed without a machine shop and without precision tooling. No compressor. No turbine. Just a second displacer/ regenerator added to what would otherwise be an ordinary LTD Stirling. And well... Some additional linkage.

The important thing of course is the timming of the two displacers so as to have them working in phase to effect both Stirling engine power output and Vuilleumier cycle cooling simultaneously in the one selfsame device.